Ensure leakfree connections and seamless flow in your plumbing, industrial, or commercial applications with our premium range of Water Pipe Nipples. These fundamental threaded connectors are engineered for reliability, versatility, and longlasting performance, bridging the gap between pipes, valves, fittings, and equipment effortlessly.

Engineered for Strength & Longevity: Material Choices

We understand that different environments demand different solutions. That’s why we offer water pipe nipples in two highperformance materials:

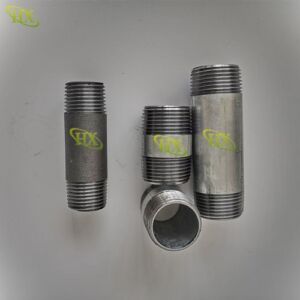

- Carbon Steel: The industry standard for strength and costeffectiveness. Our carbon steel nipples provide excellent durability for generalpurpose applications in plumbing, HVAC, fire protection, and industrial settings. Ideal for robust connections where extreme corrosion resistance isn’t the primary concern.

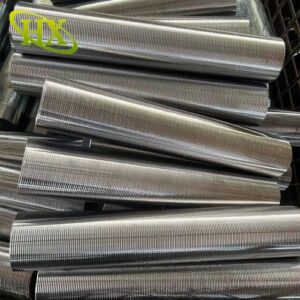

- Stainless Steel: The ultimate choice for superior corrosion resistance, hygiene, and longevity. Perfect for harsh environments, chemical processing, food & beverage, marine applications, potable water systems, and anywhere exceptional resistance to rust and oxidation is paramount. Offers outstanding strength and a clean, polished appearance.

Tailored Protection & Aesthetics: Surface Treatment

Protect your investment and match system requirements with our variety of surface treatments:

HotDip Galvanized (HDG): Provides a thick, rugged zinc coating offering maximum sacrificial corrosion protection for carbon steel nipples. Essential for outdoor applications, underground use, or environments exposed to moisture and weathering.

ElectroGalvanized (EG): A smoother, thinner zinc coating applied electrolytically, offering good corrosion resistance and a bright finish. Suitable for indoor applications or less aggressive environments.

Black (Plain/Bare): Carbon steel nipples in their natural, uncoated state. Often used for immediate installation where painting or other coatings will be applied onsite, or in specific oil/gas applications. Requires prompt corrosion protection postinstallation.

Chromated (Geomet, Zinc Flake, or similar): Often referred to as “Chrome Plated” or “Plated” in a gold/iridescent hue, this finish provides excellent corrosion resistance, often exceeding electrogalvanizing. It offers a distinctive appearance and is frequently used for visible components or where enhanced protection is needed without the bulk of HDG. Common on stainless steel or specially treated carbon steel.

Global Compatibility: Precision Threading Standards

Achieve perfect, leaktight seals with nipples manufactured to exacting international threading standards. We supply:

British Standard Pipe (BSP): Including both BSPP (Parallel G Series) and BSPT (Tapered R Series) threads, widely used in the UK, Europe, Asia, Australia, and globally.

National Pipe Thread (NPT): The American Standard Tapered Thread prevalent in the USA, Canada, and many parts of the Americas. Ensures a tight seal through thread interference.

Deutsches Institut für Normung (DIN / ISO): Covering metric standards like DIN 2999 (ISO 71) Tapered, DIN 3852 (ISO 2281) Parallel, and other specific metric threads common in Germany and continental Europe.

Custom Threading: Other standards (e.g., JIS, specific metric) available upon request. Specify your exact thread type (tapered/parallel) and size for guaranteed compatibility.

Key Features & Benefits:

Robust Construction: Manufactured from highquality carbon or stainless steel for dependable strength and pressure handling.

LeakPrevention: Precisioncut threads ensure secure, leakfree connections when properly installed.

Corrosion Resistance: Multiple finish options protect against rust and degradation, extending system life.

Versatility: Available in various nominal diameters (NPS/DN) and lengths (close, short, long, custom) to fit diverse piping needs.

Wide Application: Essential for connecting pipes, valves, tanks, pumps, pressure gauges, water heaters, industrial machinery, irrigation systems, and countless other fluid handling setups.

Compliance: Manufactured adhering to relevant industry standards (e.g., ASTM, ASME, DIN, ISO).

Applications:

Plumbing Systems (Potable Water, Drainage)

Heating, Ventilation & Air Conditioning (HVAC)

Fire Sprinkler & Protection Systems

Industrial Process Piping

Chemical Processing

Oil & Gas (Downstream/Utility)

Water Treatment Plants

Irrigation & Agricultural Systems

Marine & Shipbuilding

General Manufacturing & Maintenance

Find Your Perfect Fit:

Whether you need the economical strength of hotdip galvanized carbon steel for an outdoor project, the pristine corrosion resistance of stainless steel for a foodgrade line, or specific BSP, NPT, or DIN threads for your global equipment, we have the water pipe nipple solution.

Searching for Reliable Water Pipe Nipples? Look no further for highquality carbon steel and stainless steel nipples in hotdip galvanized, electrogalvanized, black, chromated, and custom finishes with BSP, NPT, DIN threading. Get a quote or browse our catalog today!